Consumer- and Environment-Friendly Business Activities

Reduction of Waste through Our Long-Cherished Manufacturing Capabilities and Unique Production, Inventory, and Sales System

The Group’s value of creating products loved by customers is underpinned by its dedication to superior standards of quality and safety and optimizing inventories. Our ISO 9001-based quality control system ensures the highest levels of quality at each phase, from materials procurement through to product planning, product design, and production, by adhering to strict standards. Moreover, based on our framework of generating profits and minimizing waste throughout each stage of production, inventory management, and sales, the disposal rate of Wacoal Corp. is currently around 1%.

Development of Environment-Friendly Products along Our Path to Realizing a Sustainable Global Environment

At Wacoal, we are constantly developing and expanding our line of environment-friendly products and materials in order to address the needs of consumers for more products that respect the environment and to contribute to the realization of a sustainable global environment. Our L∞Ping environmentfriendly bras made of recycled yarn, which are slated to be released mainly at directly managed stores in spring/summer 2022, could also become a part of our material waste recycling system in the future.

Energy saving efforts in distribution

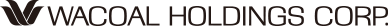

Wacoal Distribution Corp. has introduced a solar power generation system to promote corporate environmental activities and reduce power consumption. A solar energy power generation system will serve as the Shiga maximum scale as a production of electricity for enterprises.

・Roof of Wacoal Distribution's West Distribution Center(1-1 Chishiro-cho, Moriyama-shi, Shiga Prefecture, Japan)

・The rooftop installation promises to heighten the efficiency of the insulation and air-conditioning of the operating base's fifth floor.

In the fashion field, the modal shift has already been conducted ahead of other competitors in the same industry.

Acquisitions of the ISO 14001 Environmental Management System Standard and the Kyoto Environmental Management System Standard (KES) Certifications

Companies with ISO 14001 environmental management system Certification

Wacoal Corp. (Head Office Building), Wacoal Service Co., Ltd., Wacoal Distribution Corp. (Moriyama Distribution Center), and Wacoal Manufacturing Japan Corp. (Nagasaki Factory) Wacoal Art Center Co., Ltd.[Spiral], Wacoal Health Insurance Society

Companies with KES environmental management system Certification

Wacoal Manufacturing Japan Corp.(Niigata Factory), Torica Co., Ltd.

Brassiere Recycling Activities

Based on customer feedback that “bras are hard to throw away, Wacoal Corp.’s “Wacoal Bra Recycle” initiative is designed to collect and recycle unneeded bras. Through participation in JEPLAN, INC.’s BRING program, the collected bras are reborned into recycled plastic.

| FY2008 (First campaign) |

FY2022 | FY2023 | FY2024 | Cumulative total | |

|---|---|---|---|---|---|

| Number of Stores | ― | 750 | 800 | 800 | ― |

| Number of Brassieres Collected* | 30,000 | 257,000 | 240,000 | 204,000 | 3,388,200 |

* Numerical value converted at 1 unit = 100g, based on the total recovered weight